Solar PV system maintenance in accordance with the IEC 62446-1 standard

Brand: HIOKI

Category: Knowledge Activity

Solar PV system maintenance in accordance with the IEC 62446-1 standard

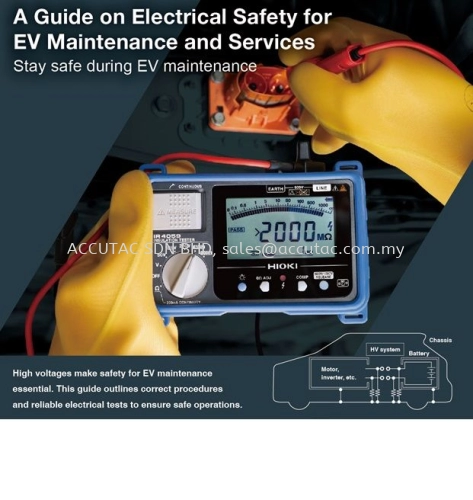

Proper maintenance is required for the safe and reliable operation of long-term solar power generation systems, so performing electrical testing on the system in accordance with international standard is important. This article discusses the DC side testing of the IEC 62446-1 standard.

About IEC 62446-1

The IEC 62446-1 is an international standard for testing, documenting, and maintaining grid-connected photovoltaic systems. It sets standards for how system designers and installers of grid-connected PV systems must provide information and documentation to customers. This standard also describes DC testing of the PV system which can be used for periodic testing of the system.

In the standard, the test is classified into categories 1 and 2 according to the size of the PV system. Category 1 refers to all solar PV generation systems, whereas Category 2 refers to larger or more complicated systems such as mega solar power plants.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inquiry - Solar PV system maintenance in accordance with the IEC 62446-1 standard